LH Series

LH Series Horizontal Labeling Machine A leading provider of labeling systems for small cylindrical containers

The Autopak LH Series revolutionizes horizontal labeling for small cylindrical products, offering a solution specifically designed for Thailand’s pharmaceutical, cosmetics, and laboratory industries. Engineered to handle products with diameters ranging from 10–25 mm in a horizontal position, our LH-X1 delivers exceptional precision at speeds of up to 30 meters per minute.

High-speed performance

up to 30 meters per minute, one of the fastest production speeds in the industry for high-volume manufacturing.

Precise handling of small diameters

Precise handling of small diameters, expertly designed for cylindrical products ranging from 10–25 mm with a horizontal orientation.

Industrial-Grade Medical Structure

Stainless steel structure made from S304, fully compliant with medical and cosmetics industry standards.

Advanced Horizontal Feeding System

A unique horizontal feed module designed for the gentle handling of delicate products.

Applications in industries where the LH Series excels

Pharmaceuticals and Medical Applications

- Labeling of syringes and ampoules

- Identification of medical test tubes

- Labeling of vaccine vials in compliance with regulatory requirements

- Marking of pharmaceutical sample containers

Cosmetics and Personal Care Products

- Labeling of lipstick tubes

- Marking of eye cream and serum containers

- Identification of nail polish bottles

- Labeling of perfume sample vials

Laboratory and Research Activities

- Identification of test tubes in the laboratory

- Labeling of research sample containers

- Marking of chemical reagent tubes

- Identification of tissue sample containers

Specialized Production

- Labeling of electronic component tubes

- Marking of industrial adhesive tools

- Identification of precision instruments

- Labeling of quality control samples

LH-X1 Superior Innovation for Horizontal Labeling

Advanced Horizontal Workpiece Feeding System

Key Features: Specialized horizontal feeding module designed for handling delicate products.

Advantages: Prevents product damage during the labeling process.

Applications: Ideal for fragile tubes, test tubes, and components that require precise handling.

Specialized expertise for small-sized products

Product range: diameter 10–25 mm (expandable up to 35 mm, although operational speed may decrease)

Supported height range: 20–150 mm, accommodating a wide variety of product sizes.

Accuracy: Specifically designed for small cylindrical products

Maximum Performance Speed

Speed: Up to 30 meters per minute the fastest in the Autopak lineup.

Performance: Robust structure with a 200 kg capacity, designed for continuous operation.

Suitable for high-volume pharmaceutical and cosmetic production lines.

Compliance with Standards: Accurate and consistent labeling ensures adherence to Thai FDA regulations as well as international pharmaceutical standards.

Protecting Fragile Products: The horizontal conveying system has been engineered to ensure minimal damage to delicate pharmaceutical bottles and packaging containers.

Enhancing production efficiency: With consistent operation, supports high-capacity pharmaceutical and cosmetic production lines.

Maintaining Product Quality: Accurate labeling plays a crucial role in preserving the specified quality of products.

Details:

Model

LH-X1

Label Width

10~130 mm (unlimited length)

Labeling Speed

0~30 meters/minute (freely adjustable)

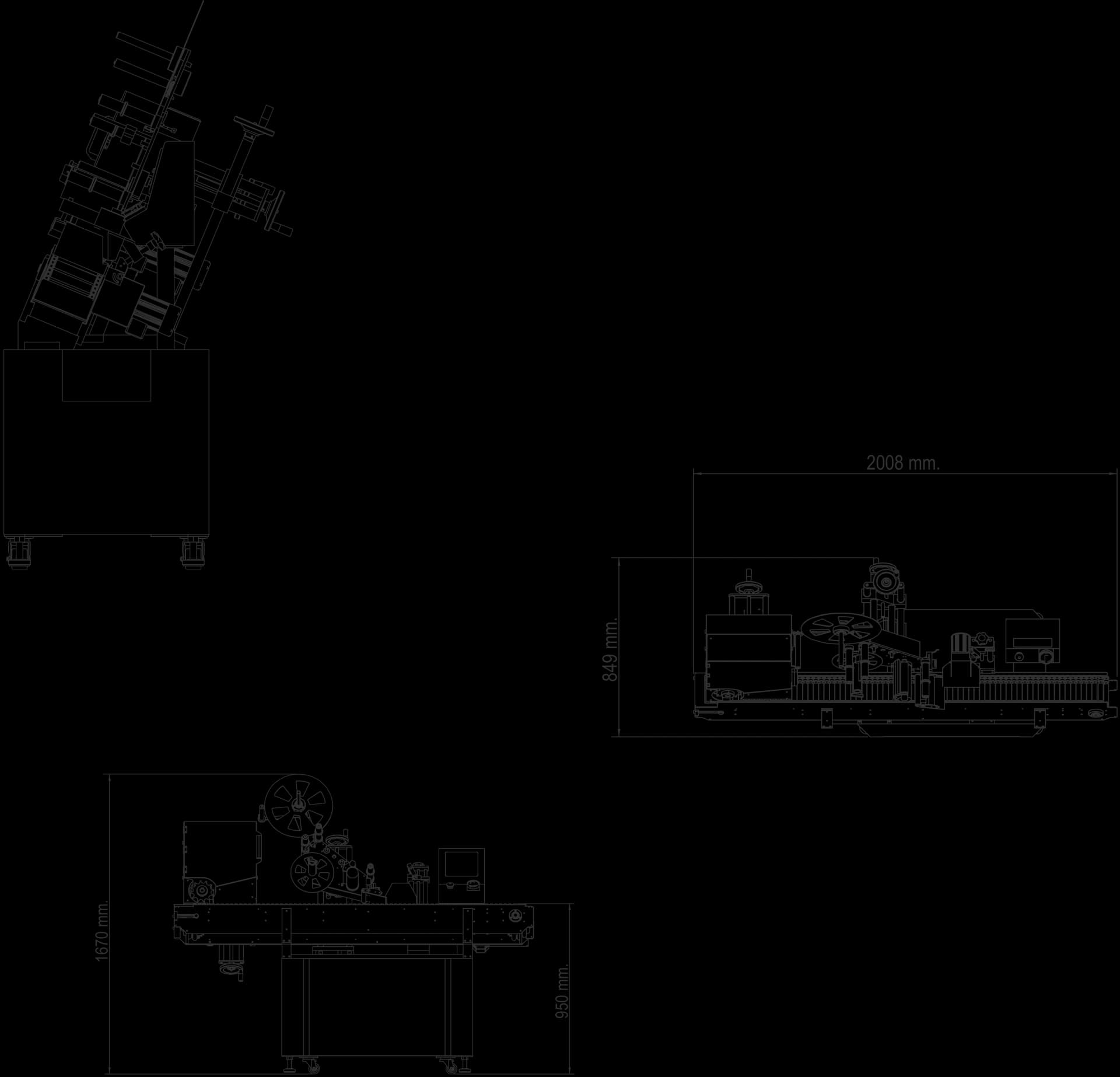

Machine Dimensions (LxWxH)

2008mm x 849mm x 1670mm

Machine Weight

Approximately 200 kg

Product Thickness

20-150 mm

Product Height

10-25 mm (custom design upon customer request)

Machine structure made from S304 stainless steel and aluminum alloy shaped with CNC system, anodized

Uses 5-phase motor (from Japan or equivalent quality grade)

Uses Panasonic high-quality driver and PLC equipment set

Touch screen set uses Fuji brand (or equivalent quality grade)

Sensor set brand SICK (from Germany or equivalent quality grade)

SICK Encoder (from Germany or equivalent quality grade)

PowerFlex inverter

Automatic voltage regulator set, range 190-270 volts

Conveyor belt width 130 mm

Conveyor belt length 2 meters

Conveyor belts can be quickly lifted to troubleshoot or make adjustments

Conveyor belt height from floor 950 mm (or as specified)

Machine size: length 2008 mm x width 849 mm x height 1670 mm

Machine weight 200 kg

Power usage: 800 watts, AC 220 volts 50/60 hertz, 1 phase

Maximum speed 30 meters per minute

Emergency stop button

Workpiece diameter: 10-24 mm (or size 25-35 mm sticker half of workpiece)

Workpiece height 20-150 mm

LH Series Options:

- Can adjust printing both vertically and horizontally

- Transparent sticker reading sensor set

- Automatic workpiece feeding set for horizontal bottles

- Position adjustment meter

- Warning light set

Label Positions

Frequently Asked Questions (FAQ)

What is the difference between LH Series and LR Series?

LH Series handles products horizontally (laid sideways) and specializes in smaller diameters (10-25mm), while LR Series handles products vertically and supports larger diameters (30-100mm). LH is suitable for vials and test tubes, LR is suitable for bottles

Can it handle pharmaceutical-grade requirements?

Yes, LH Series features S304 stainless steel structure meeting pharmaceutical manufacturing standards and includes options for regulatory labeling as required by Thai FDA and international standards

Which products are suitable for horizontal labeling?

Products that benefit from horizontal labeling include vials, test tubes, cosmetic vials, lipstick containers, and small cylindrical products that require gentle handling during the labeling process

How does the horizontal feeding module work?

The horizontal feeding module gently guides products placed on their sides and applies labels with care, preventing rolling or damage. This feature is particularly important for fragile pharmaceutical tubes and cosmetic containers.

What is the maximum product size that can be handled?

LH-X1 handles products with 10-25mm diameter and 20-150mm height. For 25-35mm diameter, it will operate with reduced throughput while maintaining labeling accuracy

Is training provided for pharmaceutical operations?

Autopak provides specialized training for pharmaceutical operations, including compliance with regulatory requirements, aseptic handling procedures, and guidance on maintenance for medical manufacturing environments.